7 Critical Standards for High-Quality PCB Manufacturing: From Material Selection to Process Control

- afax TE.

- 8 hours ago

- 3 min read

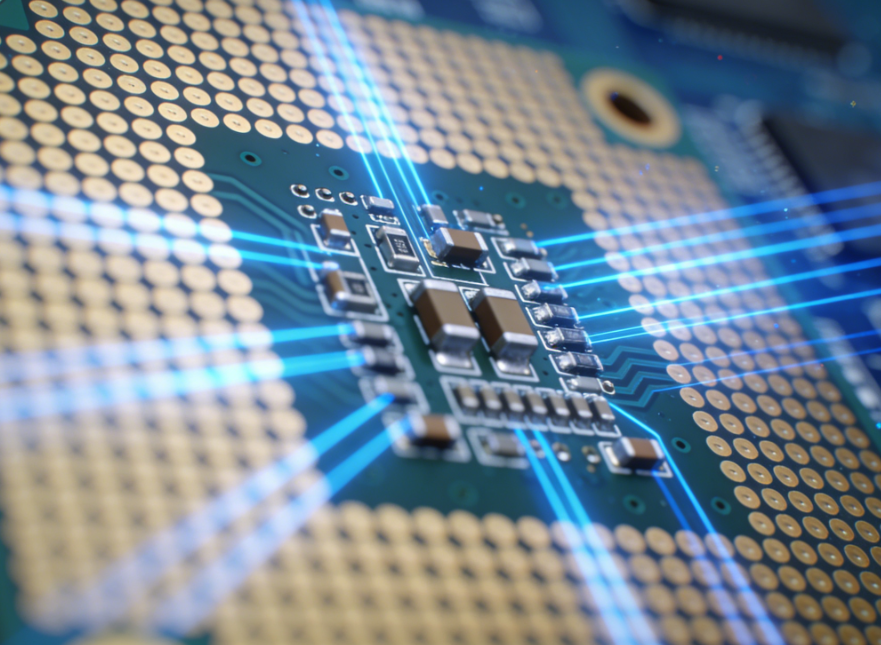

In the world of electronics, the Printed Circuit Board (PCB) is the foundational bedrock. Its quality dictates the performance, reliability, and longevity of the final product. For engineers, procurement specialists, and businesses who prioritize excellence, understanding the standards that define high-quality PCB board production is non-negotiable. This article outlines the seven critical pillars that separate superior PCBs from the mediocre, demonstrating the technical rigor essential for mission-critical applications.

1. Precision in Material Selection: The Foundation of Reliability

The journey to a high-quality PCB begins with its core materials. We insist on using premium-grade substrates from reputable suppliers.

FR-4 Standards: Utilizing high-Tg (Glass Transition Temperature) FR-4, halogen-free materials, and specialized laminates for high-frequency or high-thermal applications.

Copper Foil Quality: Consistent copper cladding with proper thickness (e.g., 1oz, 2oz) and surface profile to ensure optimal conductivity and strong bond strength.

Traceability: All materials are fully traceable, with certifications (e.g., UL, IPC) to guarantee consistency and compliance.

2. Advanced Design for Manufacturing (DFM) Analysis

Quality is engineered into the board before production begins. Our rigorous DFM process meticulously reviews customer Gerber files, identifying potential issues related to:

Annular Ring Integrity

Trace/Space Clearance

Drill Hole Alignment

Solder Mask & Silkscreen LegibilityThis proactive step prevents manufacturability flaws, reduces turnaround time, and eliminates costly post-production failures.

3. State-of-the-Art Imaging & Etching Process Control

Achieving precise circuit patterns is paramount. We employ:

Direct Laser Imaging (DLI): For superior accuracy and finer line resolution compared to traditional phototooling.

Controlled Etching Processes: Automated, precise etching systems that maintain consistent trace width and geometry, preventing over-etching or under-etching.

4. Drilling & Mechanical Accuracy

The precision of holes and cuts directly impacts component assembly and board functionality.

High-Precision CNC Drilling: Using new, sharp drill bits and automated systems for accurate hole placement and clean, burr-free walls.

Controlled Depth Drilling & Routing: Ensuring perfect alignment for vias, through-holes, and board outlines.

5. Excellence in Plating & Surface Finish

The plating process establishes electrical connectivity and protects copper from oxidation.

Uniform Copper Plating: Ensuring consistent copper deposition in through-holes (PTH) for reliable inter-layer connections.

High-Quality Surface Finishes: Offering a range of options like Electroless Nickel Immersion Gold (ENIG), Immersion Silver, HASL, and OSP, each applied with strict process control for solderability and shelf life.

6. Comprehensive Quality Control & Testing

Trust is built on verification. Our multi-layered QC protocol includes:

Automated Optical Inspection (AOI): 100% inspection for shorts, opens, and dimensional defects.

Electrical Testing: Flying Probe or Fixture-based testing to verify netlist continuity and isolation.

Microsectioning (Cross-Section Analysis): Regular destructive testing to audit internal layer alignment, plating thickness, and laminate integrity.

IPC-A-600 Compliance: Adherence to the industry's definitive acceptability standard for PCBs.

7. Controlled Soldermask & Legend Application

The final protective and identificatory layers are applied with precision.

LPI (Liquid Photoimageable) Soldermask: For a uniform, durable coating that provides excellent insulation and solder resistance.

Sharp Legend Printing: Clear, legible, and non-smudged silkscreen markings for easy assembly and debugging.

Conclusion: Partnering for Performance

High-quality PCB board production is not a single step but a holistic system of controlled processes, advanced technology, and uncompromising standards. It transforms a simple board into a reliable engine for innovation.

We don't just manufacture PCBs; we engineer reliability and build the foundation for your electronic excellence. If your projects demand circuit boards where quality is critical, let's connect.

sales03@sunsoartech.com or call +8613632793113.

Comments