Flexible Printed Circuits in Automotive Electronics: Critical Roles from Displays to Sensors

- afax TE.

- 11 minutes ago

- 3 min read

Driving Innovation: The Essential Role of FPCs in Modern Automotive Electronics

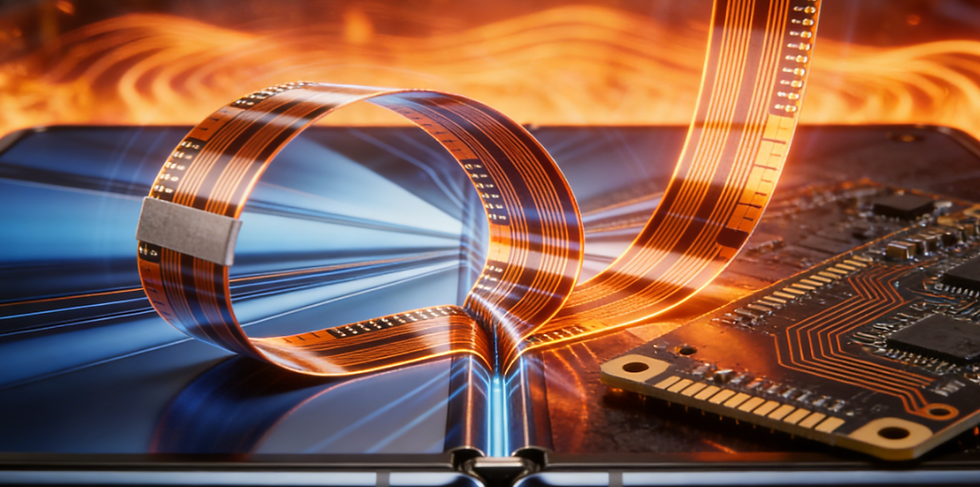

The automotive industry is undergoing a radical transformation, defined by electrification, autonomous driving, and immersive digital cockpits. At the heart of this evolution lies a critical, yet often understated, enabling technology: the Flexible Printed Circuit (FPC). Moving beyond the limitations of traditional wiring harnesses and rigid boards, FPCs provide the foundational interconnectivity for next-generation vehicle electronics. This article explores the pivotal applications of FPCs, from sophisticated in-vehicle display flexible cabling to advanced sensor networks, and demonstrates why they are integral to modern automotive electronics FPC solutions.

Why FPCs Are the Ideal Solution for Automotive Electronics

Automotive environments present unique challenges: extreme temperature fluctuations, constant vibration, limited space, and demanding reliability requirements over a 10-15 year lifespan. FPCs address these challenges head-on:

Space and Weight Savings: FPCs are thin, lightweight, and can be folded or bent into complex 3D shapes, enabling efficient packaging in tight spaces—a critical factor in sleek infotainment systems and sensor-packed assemblies.

Key Application 1: Enabling Advanced In-Vehicle Displays

The modern cockpit is dominated by digital displays—curved instrument clusters, large center stack touchscreens, head-up displays (HUDs), and rear-seat entertainment modules. In-vehicle display flexible cabling using FPCs is indispensable here.

The Challenge: Connecting a large, thin display to a main control unit requires a reliable, space-saving link that must withstand the assembly process and potential movement.

The FPC Solution: Tailored FPCs, often incorporating fine-pitch connectors, provide a robust, low-profile, and highly reliable connection. They facilitate seamless transmission of high-resolution video and touch data. In applications like rising or rotating screens, the FPC’s inherent flexibility is the only viable solution.

Case Example: A major electric vehicle manufacturer utilizes a custom, multi-layer FPC to connect a massive 17-inch central touchscreen. This automotive FPC solution is designed with specific bend radii to route behind the dashboard, surviving thousands of hours of thermal cycling and vibration while maintaining signal integrity for ultra-responsive touch and graphics.

Key Application 2: Connecting the Vehicle's Sensory Nervous System

As vehicles gain higher levels of autonomy, the number of cameras, LiDAR, radar, and ultrasonic sensors grows exponentially. FPCs are the preferred interconnect within these sensor modules and for their initial data links.

The Challenge: Sensor modules (interior cabin cameras, side-view cameras) are often small, oddly shaped, and require stable, noise-free signal transmission from the sensor to its local processor.

The FPC Solution: FPCs allow for compact, three-dimensional packaging of the sensor assembly. Their consistent impedance control ensures high-frequency signals from radar or camera sensors are transmitted without degradation. Their lightness is also crucial for small, movable assemblies like advanced driver-monitoring cameras.

Case Example: An Advanced Driver-Assistance Systems (ADAS) provider designs its front-facing camera module using a rigid-flex PCB (combining rigid and flexible sections). The FPC portion elegantly folds to connect the image sensor board to the processing board within a single, robust, and miniaturized housing. This simplifies assembly, improves reliability, and protects critical signals from EMI.

Beyond Displays and Sensors: Versatile Applications

The utility of FPCs extends across the vehicle:

Battery Management Systems (BMS): Flexible circuits monitor cell voltages and temperatures within the tight confines of an EV battery pack.

LED Lighting: For dynamic brake lights, animated turn signals, and interior ambient lighting, FPCs provide a thin substrate to mount LEDs on curved surfaces.

Steering Wheel Controls: FPCs connect buttons, paddles, and haptic feedback components, routing through the steering column's rotating assembly.

Choosing the Right Partner for Automotive FPC Solutions

Developing and manufacturing FPCs for automotive use requires specialized expertise. Key considerations include:

Material Science: Knowledge of high-temperature, flame-retardant polyimides and durable coverlays.

Adherence to Standards: Compliance with automotive-grade qualifications like AEC-Q100 and following IATF 16949 manufacturing processes.

Conclusion: FPCs as a Strategic Enabler for Automotive Innovation

From powering the immersive digital experiences on in-vehicle display flexible cabling to forming the critical nerves of ADAS sensor suites, Flexible Printed Circuits are more than just components—they are strategic enablers of automotive innovation. As vehicles evolve into software-defined, electronically complex platforms, the demand for sophisticated, reliable, and space-efficient automotive electronics FPC solutions will only intensify.

Partnering with an FPC manufacturer that possesses deep automotive application expertise is no longer optional; it is essential for bringing next-generation vehicle systems to market with the quality, durability, and performance that end-users demand.

If you have specific procurement intentions or need further assistance, please feel free to contact us at sales03@sunsoartech.com or call +8613632793113.

Comments