Flexible & Rigid-Flex PCBA: Shaping the Future of Wearable Devices

- afax TE.

- Nov 25, 2025

- 3 min read

Explore advanced flexible and rigid-flex PCBA solutions for wearable devices. Learn how our expertise in design, manufacturing, and assembly creates smaller, more reliable, and innovative consumer and medical wearables.

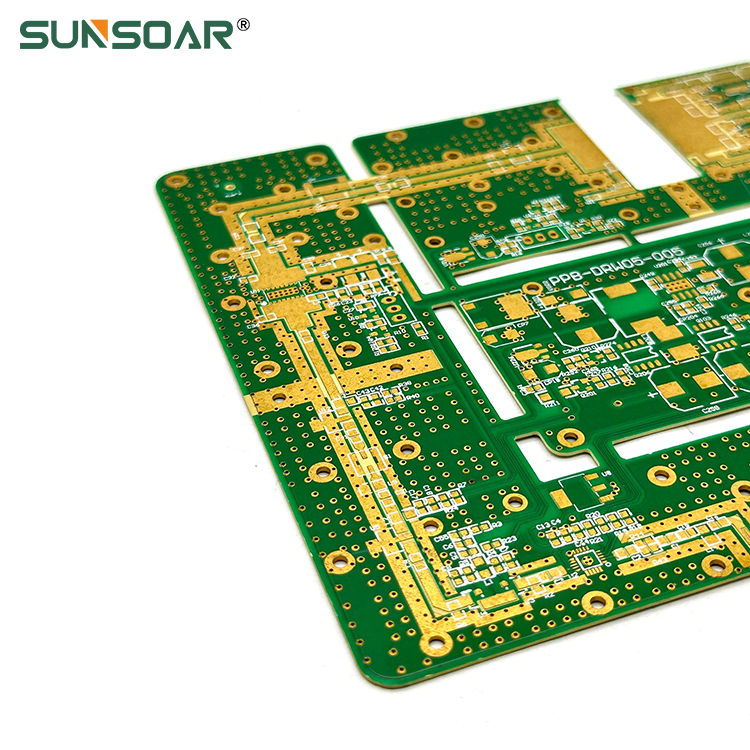

Flexible and Rigid-Flex PCBA: The Engine for Next-Generation Wearable Devices

The wearable technology revolution is demanding more from its core components. As devices shrink and conform to the human body, traditional rigid Printed Circuit Board Assemblies (PCBAs) are reaching their limits. For companies in the consumer electronics and medical device sectors, the search for innovative circuit solutions that can bend, fold, and save space ends here. The answer lies in flexible and rigid-flex PCBA solutions.

we specialize in designing, manufacturing, and assembling these advanced circuits, empowering you to create breakthrough wearable devices that are smaller, more reliable, and feature entirely new form factors.

The Limitations of Rigid Boards in Modern Wearables

Rigid PCBAs, while reliable for many applications, pose significant challenges for wearables:

Space Inefficiency: They cannot conform to curved device housings, wasting valuable space.

Weight: They add unnecessary bulk and weight, reducing comfort.

Vulnerability to Stress: Constant movement and bending can cause solder joint failures and broken traces on rigid boards.

Design Inflexibility: They severely limit industrial and ergonomic design possibilities.

How Our Flexible & Rigid-Flex PCBA Solutions Empower Your Designs

We overcome these limitations by leveraging the unique properties of flexible and rigid-flex circuits. Here’s how our expertise translates into direct benefits for your wearable products:

1. Unmatched Miniaturization and Space Savings

Flexible circuits are thin, lightweight, and can be folded or bent into tiny, unused spaces within a device. Rigid-flex boards take this further by integrating multiple rigid boards interconnected by flexible circuits, effectively creating a complex, three-dimensional circuit structure.

Our Capability: We excel in high-density interconnect (HDI) design, utilizing micro-vias and fine-pitch components to maximize functionality in a minimal footprint. This is crucial for devices like discreet hearing aids, smart rings, and advanced continuous glucose monitors.

2. Superior Reliability and Durability

By eliminating the need for connectors and cabling between multiple rigid boards—a common point of failure—rigid-flex PCBA significantly enhances overall system reliability. The flexible sections are designed to withstand thousands, even millions, of dynamic flex cycles.

Our Capability: Our engineering team performs extensive FEA (Finite Element Analysis) simulations to predict and mitigate stress in bend areas. We select appropriate materials (like PI or PET films) and specify correct bend radii to ensure longevity, which is paramount for medical wearables that must perform flawlessly.

3. Enabling Novel and Ergonomic Form Factors

This is where true innovation happens. Flexible PCBA frees you from the constraints of the rectangle, allowing circuits to be integrated into curved displays, wrapped around limbs, or folded into unconventional shapes.

Our Capability: We partner with you from the conceptual design phase. Our Design for Manufacturability (DFM) and Design for Excellence (DFX) processes ensure that even the most ambitious form factors—from rollable smart sleeves to skin-conforming patches—are not just possible but are also manufacturable at scale.

Our End-to-End Expertise: From Design to Final Assembly

Providing a truly reliable flexible rigid-flex PCBA wearable device solution requires seamless integration across the entire production process.

Collaborative Design & Engineering: We work as an extension of your team, optimizing stack-up plans, material selection, and circuit layout for performance and cost.

Precision Manufacturing: Our state-of-the-art facilities are equipped to handle the delicate processes of flex and rigid-flex fabrication, including precise coverlay application and controlled impedance management.

Advanced Assembly: We manage the complexities of assembling components on thin, flexible substrates using specialized fixtures and soldering profiles to prevent warping and ensure highest yield.

Application Spotlight

Consumer Wearables: Smartwatches, fitness trackers, AR/VR headsets, and smart clothing.

Medical Devices: ECG/EEG patches, continuous glucose monitors, drug delivery pumps, and advanced patient monitoring sensors.

Partner with a Leader in Wearable PCBA Solutions

Don't let circuit design limitations stifle your next big idea. Embrace the flexibility, reliability, and miniaturization that our flexible and rigid-flex PCBA solutions offer.

If you have specific procurement intentions or need further assistance, please feel free to contact us at sales03@sunsoartech.com or call +8613632793113.

Comments