How to Ensure Quality in PCBA: A Guide to IPC Standards and Testing Methods

- afax TE.

- Nov 6, 2025

- 3 min read

For international buyers, particularly in demanding markets like North America and Europe, product quality and reliability are non-negotiable. How can you be sure your PCBA (Printed Circuit Board Assembly) supplier delivers to these high expectations? The answer lies in their adherence to internationally recognized standards and the robustness of their testing regimen.

A professional supplier doesn't just claim quality; they validate it through a transparent, standards-driven process. This guide details the core IPC standards and testing methodologies that underpin a truly reliable PCBA quality control system.

The Foundation: Adherence to IPC Standards

IPC standards are the global language of electronics manufacturing. They provide the definitive criteria for everything from material selection to final assembly, ensuring consistency, reliability, and acceptability. For a quality-focused supplier, these are not just guidelines but mandatory requirements.

Key IPC Standards for PCBA Quality:

IPC-A-610, "Acceptability of Electronic Assemblies": This is the most widely used standard for assessing the quality of electronic assemblies. It defines the criteria for what constitutes a "Target," "Acceptable," "Defect Condition," and "Process Indicator" for virtually every aspect of the assembly, including:

Solder Joint Quality (wetting, fillets, etc.)

Component Placement and Orientation

Cleanliness and Contamination

Hardware Installation

We consider IPC-A-610 Class 2 or Class 3 as the baseline for all our production, ensuring superior workmanship for commercial, industrial, and high-reliability products.

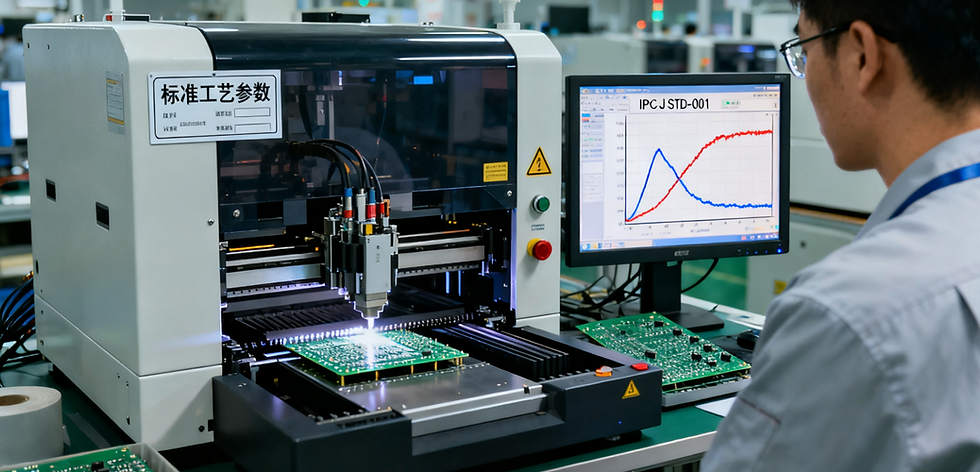

IPC J-STD-001, "Requirements for Soldered Electrical and Electronic Assemblies": This standard complements IPC-A-610 by focusing on the process of soldering. It provides detailed material, method, and verification requirements for creating high-quality soldered connections.

Our production operators and inspectors are certified to this standard, guaranteeing that our processes are designed and executed to produce reliable solder joints from the start.

"Rework, Modification and Repair of Electronic Assemblies": Even in a perfect process, occasional rework may be necessary. This standard provides the certified procedures for performing repairs without compromising the board's integrity or long-term reliability.

The Verification: Our Multi-Stage PCBA Testing Methodology

Adherence to standards defines the target; rigorous testing is how we hit it. Our quality control process is a multi-layered "defense-in-depth" strategy that catches potential defects at every stage of production.

1. Electrical Test: Flying Probe Test

Purpose: To verify the electrical integrity of the bare board and the assembled unit. It checks for short circuits, open circuits, and resistance values.

Our Application: We utilize flying probe testers for their flexibility and speed, especially for prototypes and low-to-mid volume production. They ensure the foundation of your board—the circuitry—is correct before components are even soldered.

2. Automated Optical Inspection (AOI)

Purpose: A high-speed, camera-based system to visually inspect the board after solder paste printing and component placement.

Our Application: Our AOI systems automatically detect a wide range of defects, including:

Missing or misaligned components

Polarity errors

Solder bridging (shorts)

Insufficient or excessive solder paste

3. X-Ray Inspection (AXI)

Purpose: To see what the human eye and AOI cannot. X-Ray inspection is crucial for verifying hidden solder connections.

Our Application: We deploy AXI as a critical check for:

Ball Grid Array (BGA), QFN, and other hidden-lead components: Inspecting solder ball alignment, voids, and bridging.

Through-hole pin fill: Ensuring solder has adequately wicked up into the plated through-holes.

Internal layer integrity: Identifying potential issues within complex multi-layer boards.

4. Functional Testing (FCT)

Purpose: The ultimate validation. This test simulates the final operating environment of the board.

Our Application: We develop custom functional test fixtures and software to power up the assembled PCBA and verify that it performs to its specified design parameters. This includes testing:

Power-on sequences

Input/Output signals and communication protocols (UART, I2C, SPI, USB, etc.)

Sensor readings and actuator responses

Overall system functionality and software integration

Our Quality Promise to You

For a discerning international buyer, choosing a PCBA supplier is about trust. You need a partner who speaks the same language of quality—the language of IPC standards and empirical testing data.

Our commitment is to deliver not just boards, but confidence. By building our processes on the bedrock of IPC standards and verifying every step with a comprehensive suite of electrical, optical, and functional tests, we ensure that your products are reliable, durable, and market-ready.

You can find more information about our aluminum PCBs here.

If you have specific procurement intentions or need further assistance, please feel free to contact us at sales03@sunsoartech.com or call +8613632793113.

Comments