Multilayer PCB One Step Service: Your Key to Efficient Electronic Manufacturing

- afax TE.

- Aug 12, 2025

- 4 min read

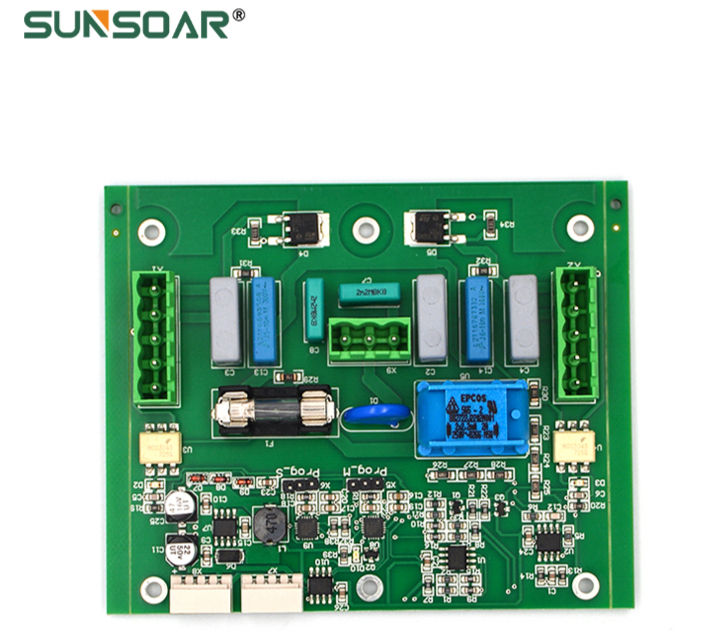

In the fast-paced world of electronics, Printed Circuit Boards (PCBs) are the unsung heroes that hold everything together. They are the foundation upon which modern electronic devices are built, providing a platform for the seamless integration of various components. Among the different types of PCBs, Multilayer PCBs have emerged as a game-changer, offering enhanced functionality and performance in a compact form factor.

Understanding PCBs: The Basics

A Printed Circuit Board, or PCB, is a flat board made of insulating material, typically fiberglass, with conductive pathways (traces) printed or etched onto it. These traces connect electronic components such as resistors, capacitors, integrated circuits, and transistors, allowing for the flow of electrical signals. PCBs come in various types, including single-sided, double-sided, and multilayer, each catering to different levels of complexity and functionality requirements.

Single-sided PCBs have conductive traces on only one side of the board, making them suitable for simple electronic applications where cost and simplicity are priorities. Double-sided PCBs, on the other hand, have traces on both sides, connected by vias (small holes filled with metal), enabling more complex circuit designs. Multilayer PCBs, as the name implies, consist of multiple layers of conductive traces separated by insulating layers. This construction allows for a higher density of components and more intricate circuit routing, making them ideal for high-performance electronics such as smartphones, computers, and aerospace systems.

The Advantages of Multilayer PCBs

Multilayer PCBs offer several key advantages over their single-sided and double-sided counterparts:

Higher Component Density: With multiple layers, more components can be placed on the board, reducing the overall size and weight of the electronic device. This is particularly crucial in applications where space is at a premium, such as wearable technology and portable electronics.

Improved Signal Integrity: The additional layers in a multilayer PCB can be used to create dedicated power and ground planes, which help to reduce electrical noise and interference, ensuring better signal integrity. This is essential for high-speed and high-frequency applications, where signal quality is critical.

Enhanced Thermal Management: Multilayer PCBs can be designed with internal layers that act as heat sinks, dissipating heat generated by components more effectively. This improves the overall thermal performance of the device, preventing overheating and extending its lifespan.

Greater Design Flexibility: The ability to route signals through multiple layers provides more design flexibility, allowing engineers to create complex and customized circuit layouts that meet the specific requirements of their applications.

The Role of the Electronic Components Bill of Materials (BOM)

The Electronic Components Bill of Materials (BOM) is a crucial document in the PCB manufacturing process. It lists all the components required to build the PCB, including their part numbers, quantities, and specifications. The BOM serves as a reference for the PCB manufacturer, ensuring that the correct components are used and that the final product meets the design requirements.

A comprehensive BOM should include detailed information about each component, such as its manufacturer, model number, description, and any special requirements or constraints. It should also include information about the sourcing of the components, including the preferred suppliers and the lead times for each component. The BOM is typically created by the PCB designer and is used by the manufacturer to order the components and assemble the PCB. Choosing the Right PCB and PCBA Manufacturer

Selecting a reliable and experienced PCB and PCBA (Printed Circuit Board Assembly) manufacturer is essential to ensure the success of your electronic project. Here are some key factors to consider when choosing a manufacturer:

1:Manufacturing Capabilities: Look for a manufacturer that has the expertise and equipment to handle the complexity of your PCB design. This includes the ability to manufacture multilayer PCBs with high precision, as well as the capability to perform component assembly using advanced techniques such as SMT and through-hole technology.

2:Quality Control: A reputable manufacturer will have a strict quality control process in place to ensure that all PCBs and PCBA assemblies meet the highest standards of quality. This includes performing thorough inspections and tests at each stage of the manufacturing process, from the incoming components to the final product.

3:Turnaround Time: Consider the manufacturer's ability to meet your project's deadlines. Look for a manufacturer that offers fast turnaround times without compromising on quality. Some manufacturers may also offer expedited services for urgent projects.

4:Cost-Effectiveness: While cost should not be the only factor in your decision, it is important to choose a manufacturer that offers competitive pricing without sacrificing quality. Look for a manufacturer that can provide you with a detailed quote that includes all the costs associated with the manufacturing process, including materials, labor, and any additional services.

5:Customer Service: A good manufacturer will provide excellent customer service, keeping you informed throughout the manufacturing process and addressing any questions or concerns you may have. Look for a manufacturer that is responsive, easy to communicate with, and willing to work with you to ensure the success of your project.

One Step Service: The Convenient Solution for Your PCB Needs

Many PCB manufacturers now offer a one-step service that combines PCB manufacturing, component sourcing, and PCBA assembly under one roof. This convenient solution can save you time, money, and hassle by eliminating the need to coordinate with multiple suppliers and service providers.

With a one-step service, you can simply provide the manufacturer with your PCB design and BOM, and they will take care of everything from sourcing the components to assembling the final product. This not only streamlines the manufacturing process but also ensures better quality control and faster turnaround times. Additionally, by working with a single provider, you can benefit from their expertise and experience in all aspects of PCB manufacturing, resulting in a higher-quality product that meets your exact specifications.

In conclusion, Multilayer PCBs are a vital component in modern electronics, offering numerous advantages over other types of PCBs. When combined with a comprehensive Electronic Components BOM and the expertise of a reliable PCB and PCBA manufacturer, they can help you bring your electronic projects to life efficiently and effectively. Whether you are a small startup or a large multinational corporation, choosing a manufacturer that offers a one-step service can simplify the manufacturing process and ensure the success of your next electronic design.

Comments