Robust PCBA Solutions for Industrial IoT and Industry 4.0 Applications

- afax TE.

- Nov 1, 2025

- 3 min read

The Demands of Industrial IoT

The promise of Industry 4.0—smarter factories, predictive maintenance, and seamless operational intelligence—hinges on the performance of countless Industrial IoT (IIoT) devices. These devices operate on the front lines, in environments far removed from the comfort of a data center. They face extreme temperatures, constant vibration, conductive dust, and significant electromagnetic interference.

For developers of these critical devices, the Printed Circuit Board Assembly (PCBA) is not just a component; it is the central nervous system that must be inherently robust, reliable, and resilient. Off-the-shelf or consumer-grade electronics simply cannot withstand these conditions.

This is where purpose-built industrial IoT PCBA solutions make the difference between a successful deployment and costly field failures.

Designing for Reliability in Harsh Environments

Our approach to IIoT PCBA is rooted in a deep understanding of industrial challenges. We build durability into every stage of the design and manufacturing process.

1. Uncompromising Environmental Durability

Industrial settings are unforgiving. Our solutions are engineered to endure.

Wide-Temperature Operation: We select components and utilize manufacturing processes that ensure stable performance across an extended temperature range, typically from -40°C to +85°C or higher. This guarantees functionality in both freezing cold storage facilities and scorching factory floors.

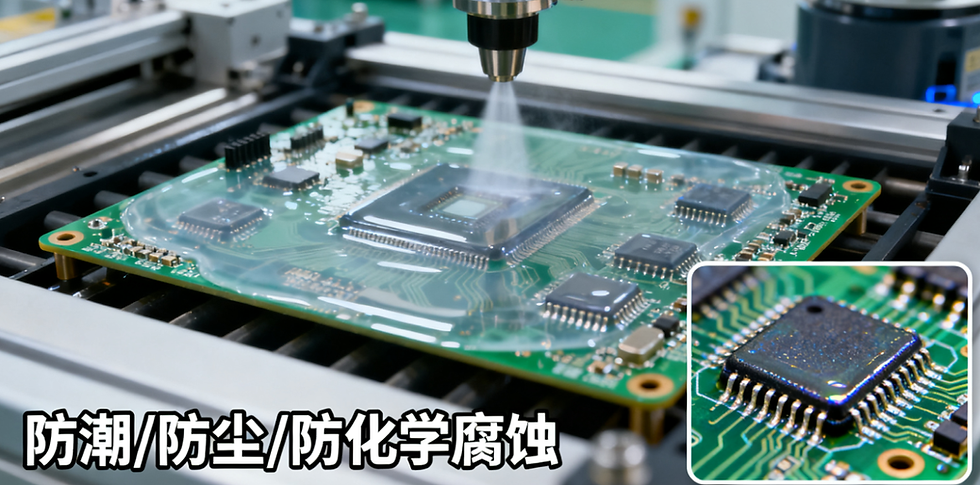

Conformal Coating: To protect against moisture, dust, chemicals, and fungal growth, we apply high-quality conformal coatings (acrylic, urethane, or silicone-based). This thin protective layer is critical for long-term reliability in harsh conditions.

Mechanical Robustness: We design for vibration and shock resistance through strategic component placement, underfill for critical BGAs, and the use of robust connectors that won't loosen over time.

2. Comprehensive Connectivity and Interface Support

The industrial world speaks a diverse language of communication protocols. Our PCBA solutions are designed to be polyglots.

Legacy Industrial Interfaces: We seamlessly integrate essential industrial interfaces like RS-485 (for robust long-distance communication) and CAN bus (for proven reliability in automotive and machinery networks).

Modern Wireless & Wired Standards: Our boards readily incorporate a full spectrum of connectivity options, including:

Wired: Gigabit Ethernet with PoE (Power over Ethernet) for simplified installation.

Wireless: 4G/LTE-Cat M1/NB-IoT, LoRaWAN, Wi-Fi, and Bluetooth Low Energy (BLE), allowing for flexible deployment in any infrastructure.

Expansive I/O: We provide a rich set of analog and digital I/O ports to interface with a wide array of sensors, actuators, and legacy equipment.

3. Optimized Low-Power Design for Deployed Longevity

Many IIoT devices are battery-powered or placed in locations where power is scarce. Intelligent power management is not a feature; it is a requirement.

Power-Efficient Component Selection: We prioritize ICs and semiconductors with low quiescent current and high efficiency ratings across all operating modes.

Advanced Power Architecture: Our designs implement sophisticated power gating and multiple sleep modes (deep sleep, hibernation), dramatically reducing average power consumption and extending battery life for years.

Power Harvesting Readiness: We design with the future in mind, creating PCBA architectures that can easily integrate with energy harvesting systems such as solar, thermal, or vibrational sources.

4. Superior Electromagnetic Compatibility (EMC) Design

In electrically noisy industrial environments, preventing both internal malfunctions and emitted interference is paramount.

EMI Mitigation: We employ best-practice design techniques—including proper grounding schemes, strategic layer stacking, and the use of shielding cans—to minimize electromagnetic emissions and susceptibility.

Signal Integrity Focus: Careful PCB layout ensures clean signal transmission, even in the presence of high-noise motors and drives, preventing data corruption and ensuring operational accuracy.

Partner for Your Industrial Evolution

Choosing a PCBA partner for IIoT is a strategic decision. It requires a vendor that understands not just board assembly, but the rigorous demands of the industrial landscape.

We move beyond simple manufacturing to become your solution provider. We offer industrial PCBA solutions that are built to last, perform reliably under pressure, and capture the data that drives your operational efficiency.

Contact us today to discuss how our robust PCBA design and manufacturing expertise can bring reliability and intelligence to your industrial operations.

Comments