Robust PCBA Solutions for Industrial IoT and Industry 4.0 Applications

- afax TE.

- Nov 6, 2025

- 3 min read

The promise of Industrial IoT (IIoT) and Industry 4.0 hinges on data—collecting it, communicating it, and acting on it. But in factory floors, outdoor installations, and harsh environments, the hardware that makes this possible faces relentless challenges. Extreme temperatures, vibration, electrical noise, and the need for 24/7 reliability can cause standard electronics to fail.

For IIoT device developers, the core Printed Circuit Board Assembly (PCBA) is not just a component; it's the heart of your product's resilience and performance. It requires a specialized design and manufacturing philosophy focused on robustness above all else.

Here’s how we engineer PCBA solutions to thrive in the demanding world of Industrial IoT.

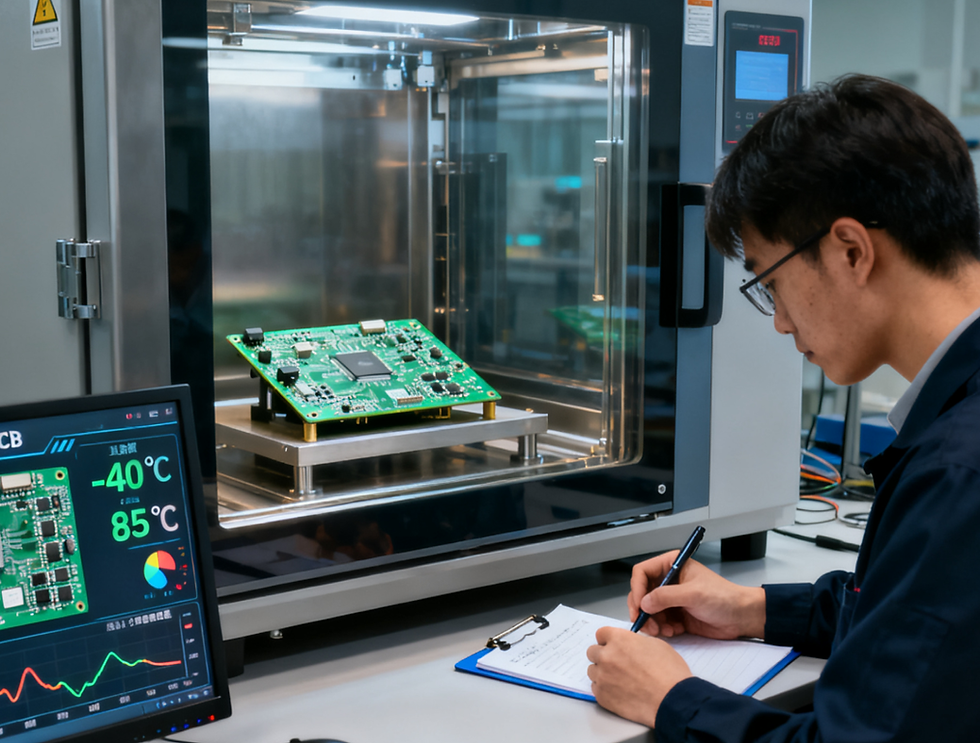

1. Designed for Wide-Temperature & Harsh Environments

Industrial settings don't operate at room temperature. From the freezing cold of an unheated warehouse to the scorching heat near industrial machinery, your devices must perform consistently.

Our Implementation:

Component Selection: We strictly source components rated for extended temperature ranges, typically -40°C to +85°C or higher, ensuring stability and longevity where commercial-grade parts would degrade.

Conformal Coating: A critical step for protection against moisture, dust, chemicals, and fungal growth. We apply acrylic, urethane, or silicone-based conformal coatings based on your specific environmental threats, significantly enhancing board reliability.

Robust Layout & Material Choice: We use high-Tg (Glass Transition Temperature) PCB substrates that resist warping and delamination under thermal stress, and design layouts to manage thermal dissipation effectively.

2. Support for Critical Industrial Communication Protocols

Interoperability is key in a connected factory. Your IIoT devices need to speak the language of existing industrial equipment, from legacy systems to modern controllers.

Our Implementation:We design PCBs with the connectivity you need, integrating interfaces for:

RS-485 & RS-422: For robust, long-distance, noise-resistant serial communication.

CAN Bus: The backbone of automotive and industrial automation for reliable multi-node networks.

Ethernet (with PoE Capability): For high-speed data and power over a single cable.

Wireless Options: Integrated modules for LoRaWAN (long-range, low-power), Cellular (4G/LTE-Cat M1/NB-IoT), and Wi-Fi/Bluetooth for flexible deployment.

3. Advanced Low-Power Design for Extended Deployment

Many IIoT sensors are deployed in remote or hard-to-reach locations, running on battery or harvested energy. Maximizing operational life through exceptional power efficiency is paramount.

Our Implementation:

Power-Optimized Architecture: We select microcontrollers with ultra-low-power sleep and active modes and design power rails for maximum efficiency.

Strategic Power Gating: The design allows for unused sections of the board to be completely powered down when not in active use.

Firmware Collaboration: We work with your firmware team to implement best practices for power management, such as aggressive sleep cycles and event-driven wake-ups, turning your device from "always-on" to "always-available."

4. Engineered for Electromagnetic Compatibility (EMC)

Industrial environments are electrically noisy, filled with EMI from motors, drives, and radio transmitters. A PCBA must be both immune to this noise to prevent malfunctions and must not itself emit excessive interference.

Our Implementation:

Robust PCB Layout: This is the first line of defense. We employ techniques like:

Proper ground plane design and partitioning.

Strategic component placement and routing to minimize loop areas.

Impedance control and termination for high-speed signals.

Shielding & Filtering: We incorporate board-level shields (BLS) and use filter networks on all I/O and power lines to suppress both incoming and outgoing electromagnetic noise.

Pre-Compliance Testing: We conduct in-house pre-compliance EMC testing to identify and mitigate issues early, de-risking your final certification to standards like CE, FCC, and industrial-specific norms.

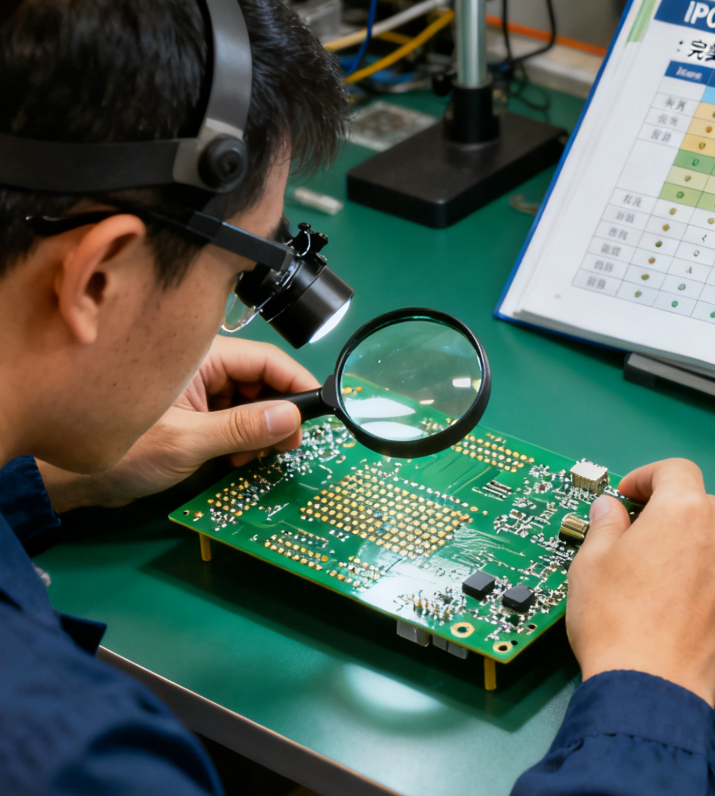

5. Quality Built on Industrial-Grade Standards

Reliability cannot be an afterthought. It must be baked into the entire manufacturing process.

Our Implementation:Our production follows IPC-A-610 Class 2/3 standards as a baseline, ensuring superior workmanship. We validate this with a rigorous testing regimen:

Automated Optical Inspection (AOI) and X-Ray to verify solder joint integrity, especially for BGA and micro-components.

Functional Testing (FCT) that simulates real-world operating conditions, including temperature cycling and communication stress tests.

Partner for Uncompromising IIoT Reliability

Developing a successful IIoT device requires more than just assembling components on a board. It demands a deep understanding of the environmental, operational, and regulatory challenges of industrial applications.

We partner with IIoT innovators to deliver PCBA solutions that are not just functional, but fundamentally robust, reliable, and ready for the field.

Let's engineer a solution that stands up to your toughest environment

You can find more information about our aluminum PCBs here.

If you have specific procurement intentions or need further assistance, please feel free to contact us at sales03@sunsoartech.com or call +8613632793113.

Comments