Understanding and Resolving PCB Soldering Defects: Bridging & Cold Joints

- afax TE.

- Dec 19, 2025

- 3 min read

Soldering defects such as bridging and cold solder joints (virtual soldering) are among the most common and critical challenges in PCB assembly. These issues not only impact product reliability and performance but can also lead to significant rework costs and production delays. This technical guide examines the root causes of these defects and provides actionable solutions for engineers and procurement professionals seeking to enhance manufacturing quality.

Part 1: Solder Bridging — Causes and Solutions

Solder bridging occurs when excess solder creates an unintended conductive connection between two or more adjacent pins or pads, leading to short circuits.

Common Causes:

Incorrect Solder Paste Application

Excessive solder paste volume due to improper stencil thickness or aperture design.

Misalignment between the stencil and PCB pads.

Poor Pad or Component Layout

Inadequate clearance between fine-pitch components (e.g., QFP, BGA).

Asymmetric or overly large pad designs.

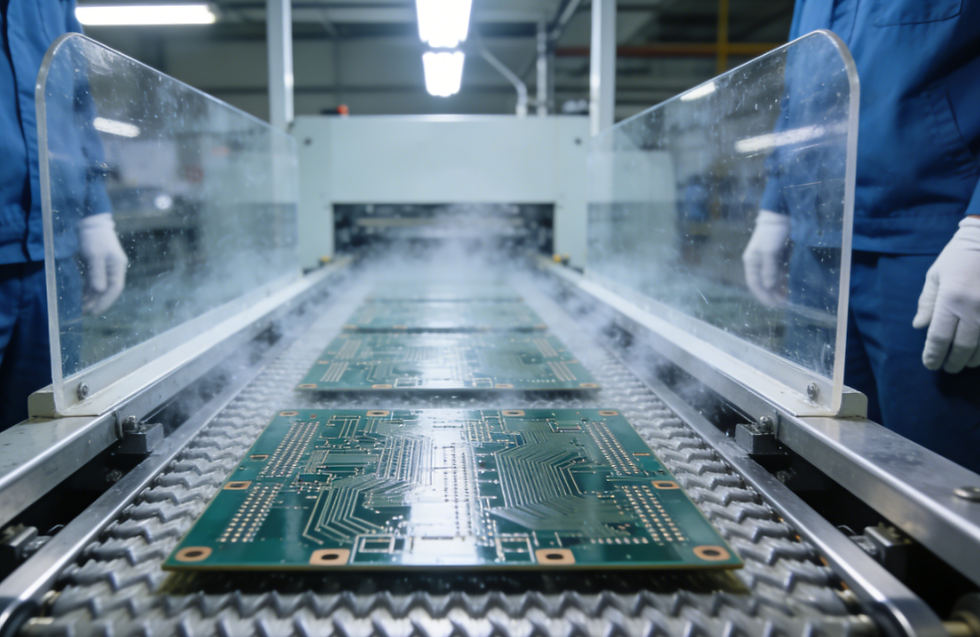

Reflow Soldering Profile Issues

Excessive peak temperature or too long a time above liquidus, causing excessive solder flow.

Uneven heating leading to solder wicking.

Solder Paste Quality

Low viscosity or poor metal content in solder paste.

Slumping of solder paste before reflow.

Component Placement Issues

Incorrect placement pressure or misalignment causing solder paste to spread.

Solutions:

Optimize Stencil Design: Reduce aperture size or thickness for fine-pitch components; consider stepped stencils for mixed component sizes.

Refine Reflow Profile: Adjust preheat, soak, and cooling rates to ensure controlled solder melting and solidification.

Improve PCB Design: Increase spacing between pads where possible; incorporate solder thieves or solder mask dams.

Material Control: Use high-quality solder paste with appropriate viscosity and particle size; ensure proper storage and handling.

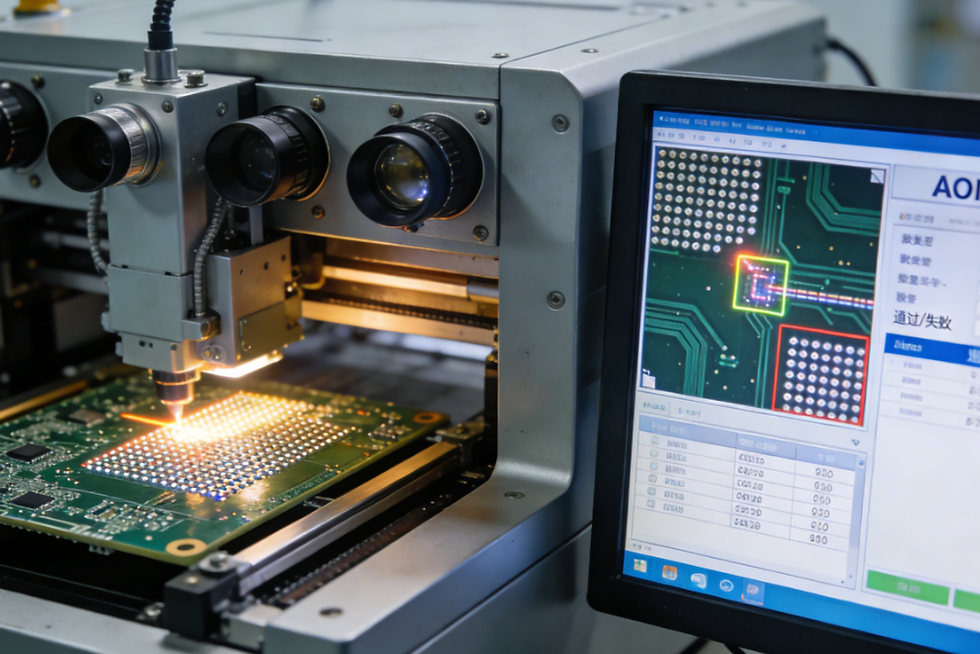

Automated Optical Inspection (AOI): Implement post-solder inspection to detect bridging before final testing.

Part 2: Cold Solder Joints (Virtual Soldering) — Causes and Solutions

A cold solder joint occurs when the solder fails to melt completely or solidifies improperly, resulting in a weak, intermittent, or non-conductive connection.

Common Causes:

Insufficient Heat During Soldering

In reflow: Inadequate peak temperature or insufficient time above liquidus.

In wave soldering: Low solder wave temperature or insufficient contact time.

In hand soldering: Incorrect iron temperature or technique.

Contaminated Surfaces

Oxidation on component leads or PCB pads.

Presence of grease, dust, or residual flux.

Poor Solderability

Use of old or oxidized solder paste.

Incompatible surface finishes (e.g., oxidation of OSP finish).

Mechanical Disturbance

Vibration or movement of the component during solder solidification.

PCB flexing during cooling.

Incorrect Solder Alloy or Flux Activity

Alloy with inadequate wetting properties.

Weak or expired flux.

Solutions:

Temperature Profile Optimization: Validate reflow profiles with thermocouples; ensure all joints reach sufficient temperature.

Surface Preparation: Implement proper cleaning and storage; use nitrogen atmosphere in reflow if necessary.

Material Management: Monitor solder paste shelf life; adopt first-in-first-out (FIFO) practices.

Process Control: Minimize board handling during cooling; ensure stable conveyor systems.

Enhanced Inspection: Use X-ray inspection for hidden joints (BGA); perform regular shear or pull testing for quality verification.

Part 3: Prevention Strategy — Integrating Best Practices

A proactive approach combines design, process, and inspection:

Design for Manufacturing (DFM): Involve process engineers early in layout to avoid problematic geometries.

Process Qualification: Conduct thorough process capability studies (CpK) for new designs.

Training & Documentation: Ensure operators are trained on standards (e.g., IPC-A-610).

Preventive Maintenance: Regularly calibrate soldering equipment and inspect wear parts.

Root Cause Analysis: Use tools like 5 Whys or Fishbone diagrams when defects occur, focusing on systemic fixes.

Conclusion

Soldering defects like bridging and cold joints are largely preventable through systematic design optimization, precise process control, and rigorous material management. By understanding their underlying causes and implementing targeted solutions, manufacturers can significantly improve first-pass yield, enhance product reliability, and reduce costly rework. Investing in prevention not only strengthens technical capability but also builds a reputation for quality—a key differentiator in competitive electronics markets.

If you have specific procurement intentions or need further assistance, please feel free to contact us at sales03@sunsoartech.com or call +8613632793113.

Comments